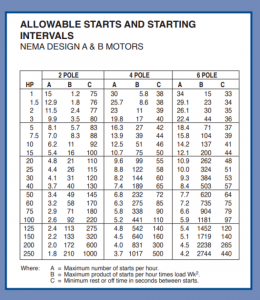

Do you know the number of allowed starts in one hour. For NEMA A and B motors operating within allowed variations of voltage and frequency, there are actually three categories related to starts, but two of those categories are fairly easy to apply. For this tip we will be focusing on the two that are easy to apply:

- Maximum number of starts per hour

- Minimum rest (off time) between starts

Let’s start with two general thumb rules:

- The smaller the horse power (HP), the more starts allowed per hour

- The slower the motor (higher # of poles), the more starts allowed per hour

A 10 HP 2 pole motor is allowed 6.2 starts per hour with a 92 seconds off time before the next start. A 10 HP 6 pole motor is allowed 14.2 starts per hour with a 41 seconds off time before the next start. That’s more than twice the number of starts and less than half the off time when going from a 2 pole to a 6 pole motor. For a larger 250 HP 2 pole motor you are only allowed 1.8 starts per hour with a 1000 seconds off time. Change that to a 250 HP 6 pole motor and you get 4.2 starts per hour with a 440 seconds off time. According to NEMA (National Electrical Manufacturer Association), the inertia of the load, motor HP, and speed (# of poles) are the determining variables. The extreme heating that occurs during startup demands that you stay within these start guidelines to prevent premature damage and reduced life expectancy for your electric motors. So not only should you track the lifetime starts of your electric motor, but also track the number of starts and start times per hour.