Early Identification of Bearing Failure Saves Company Thousands

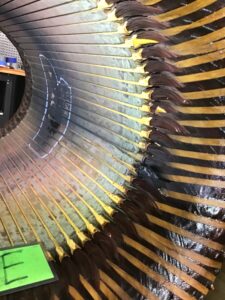

The early detection and prevention of catastrophic bearing failures alone has justified the existence of predictive maintenance departments within industrial facilities. For this Decatur Industrial customer, ongoing mechanical bearing failures in the same dryer section of their equipment was a reoccurring problem.

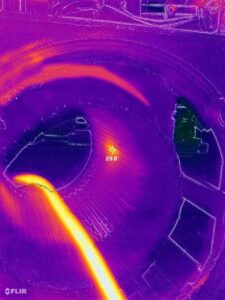

Our experts were brought in to work with the customer’s electrical team to evaluate the motors in the dryer section where they were seeing premature bearing failures. We were able to identify a bearing failure during a vibration analysis on a critical piece of equipment. It would have eventually progressed and caused an unplanned shutdown.

By identifying the failure early, we prevented a catastrophic failure that would have led to a costly repair or replacement along with associated downtime cost. Instead, we performed a more “routine” repair allowing the customer to get up and running in the most cost-effective way with planned downtime.

Click on individual images to enlarge.