Skeleton crews, required social distancing, and more are effecting customer facilities across the MidWest. Outside help and expertise is needed more than ever. Decatur Industrial understands our role in serving as an extension to your team.

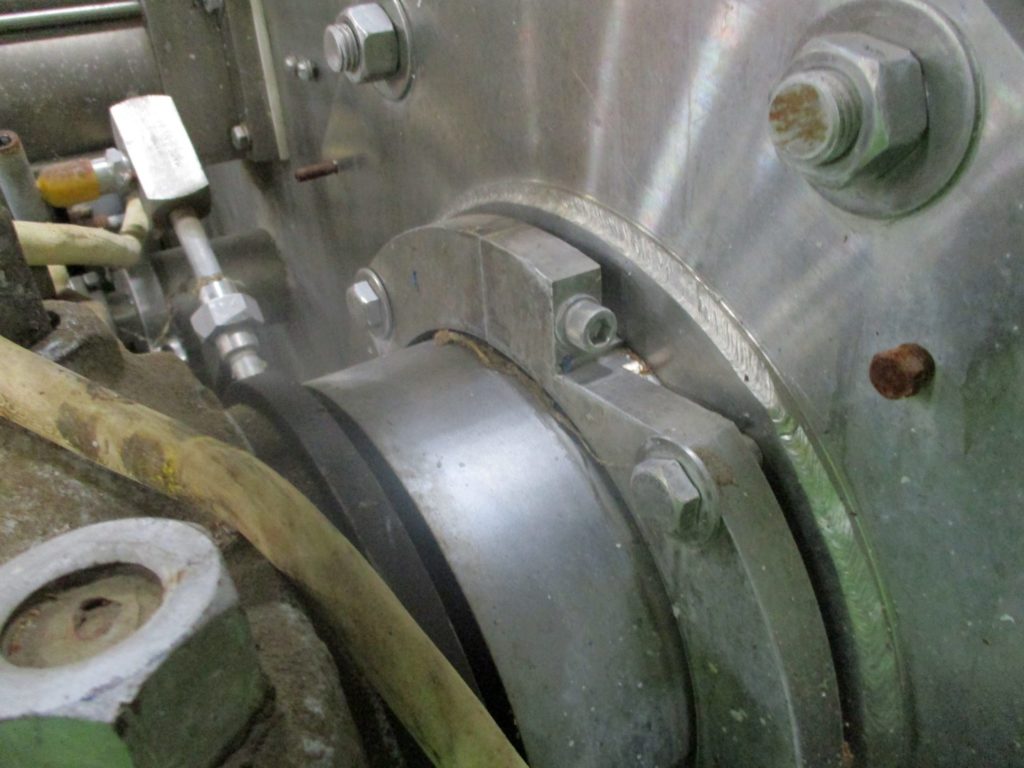

This large integrated steel producer was experiencing water inside their 15HP DC motors which was resulting in emergency repairs due to water ingress. Our team repaired the failed motors quickly and provided Lexan covers allowing the customer maintenance personnel to visually check motors for unusual brush wear, commutator condition and water.

The customer was engaged to discuss solutions to reduce issues being seen on the motors. D.I.E. recommended that no silicone sealants be used on the motor covers to reduce brush swelling and recommended a sealant that would work best for the application. Plus:

- Add an additional bolt to each side of the Lexan covers

- Increase thickness of Lexan cover

- Use a non-silicone sealant

This simple modification resulted in decreases in motor failures and extended life expectancy of motors in service.

While we focus on protecting the health of our employees and their families, we also want to alleviate any business concerns you may have during this time. Our facility is open and continues to run multiple shifts; focusing on the social distancing of employees while working to repair and return your critical assets as quickly as possible.

In addition, we are encouraged to report that so far, none of our suppliers have reported delays in shipments or problems fulfilling orders due to COVID 19.