(scroll to bottom for picture)

Do you have an MMP at your facility? The benefits can truly pay for the program itself as one Decatur Industrial customer discovered. Moreover, the planned maintenance of equipment will help to improve equipment life and help avoid any unplanned downtime. A successful preventive maintenance program is dependent on the cooperation of all the parties involved. In this case, the partnership between this metal finishing customer and Decatur Industrial Electric worked just like it should have.

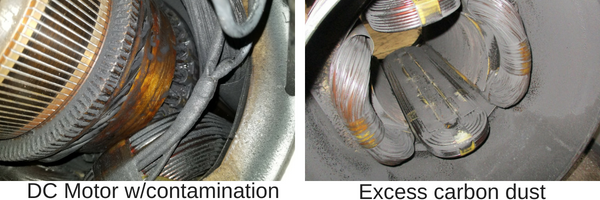

While performing a preventative maintenance walk about, our technician noticed new blowers put on the reverse side of the motors. This would not be an issue if the air louvers were reversed as well. However, this was not the case. We recommended fixing this issue during their upcoming scheduled outage. We will switch the louvered covers to the opposite end and close up the bottom louvers in place. This will redirect air flow through the motors to achieve proper cooling.

If this issue would not have been caught and the motor would have continued to run as is the customer would have experienced a premature failing due to overheating. They would be looking at a $30,000 cost for a “special” DC motor replacement or a $22,000 repair. Instead, they are looking at less than $2,000 for the work to be performed.

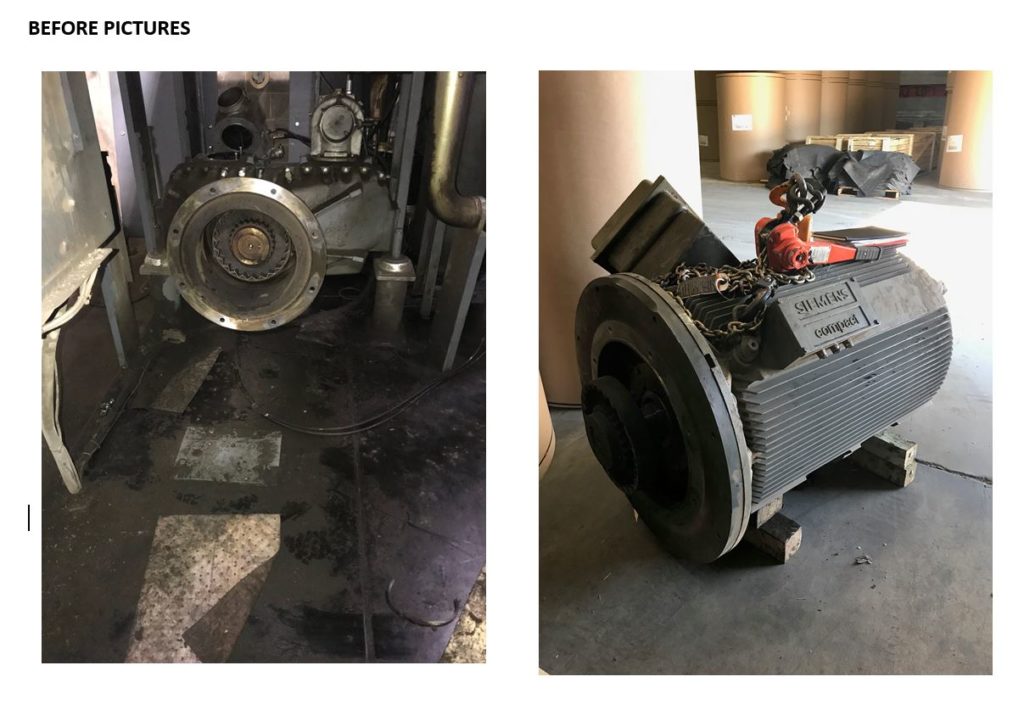

Pictured below is the motor as is which is causing airflow problems.