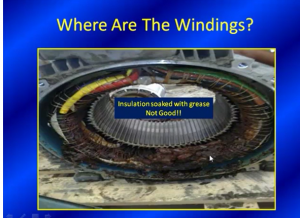

Even in the winter months a motor can overheat. Especially if snow or ice covers the air vents and prevents air from circulating on open drip proof designs. Motors running at design temperature should have an average insulation life expectancy of 20,000 running hours. Running motors hotter than design will reduce insulation life and running motors cooler than design will increase insulation life.

Not all motors have the luxury of being installed into a nice cool winter environment, so a review of the design temperature is important. Most motors have an ambient temperature rating of 40°C and an insulation class (A,B,F or H) listed on the motor nameplate. If your motor nameplate says insulation class B you can open your Electrical Engineering Pocket Handbook by EASA and see the temperature rating for Class B insulation is 130°C. So how does 130°C insulation rating and 40°C ambient temperature rating relate? Well, this means that if you start your motor with an ambient (outside air) temperature of 40°C, the internal insulation temperature should not exceed the insulation rating of 130°C. In a T-Frame Totally Enclosed Fan Cooled motor with Class B insulation an 80°C temperature rise is expected. Temperature Rise is the differential temperature from the ambient temperature and the internal winding temperature. So at full load and 40°C ambient with an 80°C rise, the surface temperature could reach 120°C (40°C+80°C). The 10°C difference (120°C vs. 130°C) is for hot spot allowance that may occur deep in the stator winding slots.

Even in winter months don’t be too quick to test the surface temperature of your motor with a bare hand. Surface temperature depends on many cooling design factors, but for a standard T-Frame motor, surface temperatures may reach as high as 95°C (203°F) and still be considered normal. Ouch! So don’t let snow and ice cover air vents and do be careful what you touch.

To see what happens to overheated insulation visit the PdMA YouTube Channel at: https://www.youtube.com/watch?v=Vt0cO1jHnKA

Source: PdMA