Making time for a motor survey and spares audit.

You know your plant and criticality of equipment & we know motors!

Do you know what equipment you have in your plant? The unfortunate truth is that if you are like many others, you don’t!

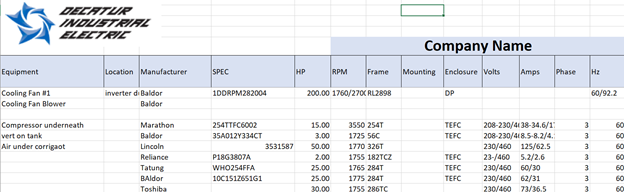

Decatur Industrial recently helped a customer perform an equipment survey so they understand exactly what they have on hand, especially as it relates to critical equipment.

Our reliability specialist worked with the customer team to survey motors in the plant line by line. We created a list of motors and equipment plus outlined which critical ones need to have spares stocked and ready to go. This list is updated and visible to the customer and Decatur Industrial at all times.

By capturing this data, we can help ensure the customer has immediate access to critical equipment and prevent unnecessary downtime, which can cost up to $25,000 an hour.

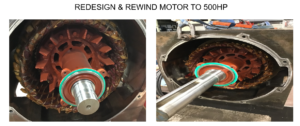

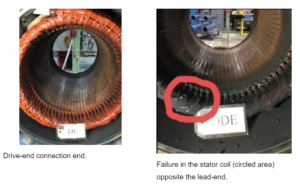

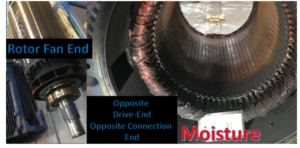

Lastly, we reviewed the motor for opportunities to improve performance. The OEM winding design was not optimal as it produced high voltage stresses within the stator. D.I.E. redesigned the winding for better performance and increased reliability. The new winding has:

Lastly, we reviewed the motor for opportunities to improve performance. The OEM winding design was not optimal as it produced high voltage stresses within the stator. D.I.E. redesigned the winding for better performance and increased reliability. The new winding has: