Decatur Industrial Electric Saves Steel Customer through our Start-Up Process

One of the most effective strategies for avoiding unplanned interruptions is correct installation at the beginning of the equipment’s life. If installation and commissioning is carried out carefully using the correct procedures, it is an investment in the machine´s serviceability and reliability for its entire service life.

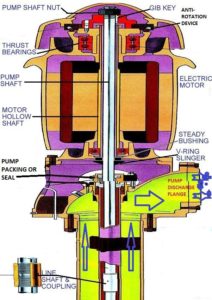

In this situation, a customer was looking to install vertical pump motors but they were having issues with the process. Decatur Industrial was engaged and proposed putting together an “install kit” for each of their groups of vertical pump applications. After reviewing the equipment, our experts came up with the kit components.

Each kit has the following to discreetly address the mechanics needs for installation.

(1) HEAD SHAFT

(1) HEAD SHAFT NUT

(1) LINE SHAFT COUPLING

(1) GIB KEY

(1) V-RING

We added the V-Ring as a failsafe, as it is non-standard and new for the application. It will sit immediately below the steady-bushing once it has been locked in place. This prevents water from being forced between the shaft and the steady bushing bore.

By engaging Decatur Industrial Electric these kits allowed for proper installation and commissioning; and most likely a long life for these vertical pump motors.

Next steps: Vibration analysis, oil sampling, and electrical testing to monitor the motors health.