(Scroll to bottom for pictures.)

There is a saying that we are all familiar with “make the best out of a bad situation”– something our country knows all too well right now. This customer had a bad situation but with Root Cause Failure Analysis (RCFA) performed by our technicians, we were able to find a long-term solution to mitigate and protect against future operator induced failures.

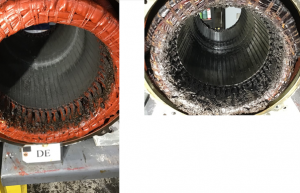

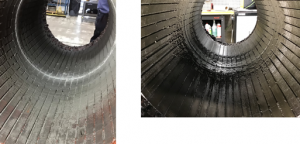

This D.I.E customer had been suffering multiple failures of their 250 HP motors. During the RCFA, we noted the shafts would not rotate. Upon disassembly we noted a potential lubrication issue as grease had been sprayed over the stator windings typically a potential sign of excessive lubrication. We discovered the rotor bars were melted at the center of the rotor core usually caused by stalling or excessive load in conditions where the rotor cannot accelerate to full speed. The resulting excessive rotor slip, and lack of acceleration, lead to high frequency and current at the rotor surface.

As a valued reliability partner we provided support during the consideration of methods to mitigate future failures from suspected thermal overload due to stalling or repetitive starting issues. We presented our findings to the customer. They have proposed the installation of Reduced-Voltage-Soft -Starters (RVSS) to their management as a best practice solution to prevent future losses on these applications. To install RVSS starters on three pieces of equipment would require a roughly $70,000 investment. The customer has has found that more than $70,000 annually was invested in motor replacements for these applications. This does not include the removal, installation, or for the production losses incurred.

Click on photos to enlarge.