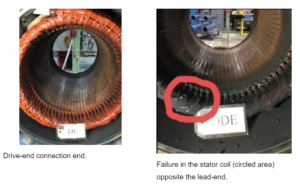

A Decatur Industrial customer had back-to-back motor failures on a 300HP boiler fan. This was a critical application and the failures greatly impacted plant production.

Issues often occurred during startup from maintenance outages while the fan was being energized or a short time later when the unit had reached speed.

We needed to do two things: On-site evaluation + motor disassembly and RCFA in shop.

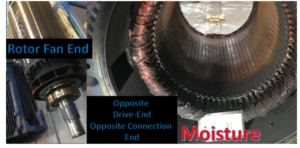

The motor was found to have failed due to moisture condensing on the windings. When the units were offline for maintenance, they failed to have the proper accessories to prevent moisture. D.I.E. installed silicone space heaters on the winding.

On-site inspection found a steam leak in an adjacent area that vented into the room where the motor was sitting idle during the outages. The customer needed to the change the venting to send the energy outside the building for the steam to be released.

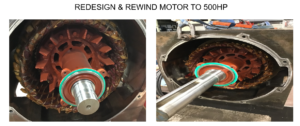

Lastly, we reviewed the motor for opportunities to improve performance. The OEM winding design was not optimal as it produced high voltage stresses within the stator. D.I.E. redesigned the winding for better performance and increased reliability. The new winding has:

Lastly, we reviewed the motor for opportunities to improve performance. The OEM winding design was not optimal as it produced high voltage stresses within the stator. D.I.E. redesigned the winding for better performance and increased reliability. The new winding has:

- 50% less voltage, at 77 volts per coil

- 300% more phase-to-phase and coil-to-coil insulation

- Air gap harmonics mitigation

- Optimum Chord factor where each turn produces higher torque

- 10% increase in the circular-mil-per-ampere area of wire allowing the motor to operate cooler under the same load due to reduced copper losses

- Rewound/Repaired Motor $15,000

- Replacement Motor $25,500